SERVICES

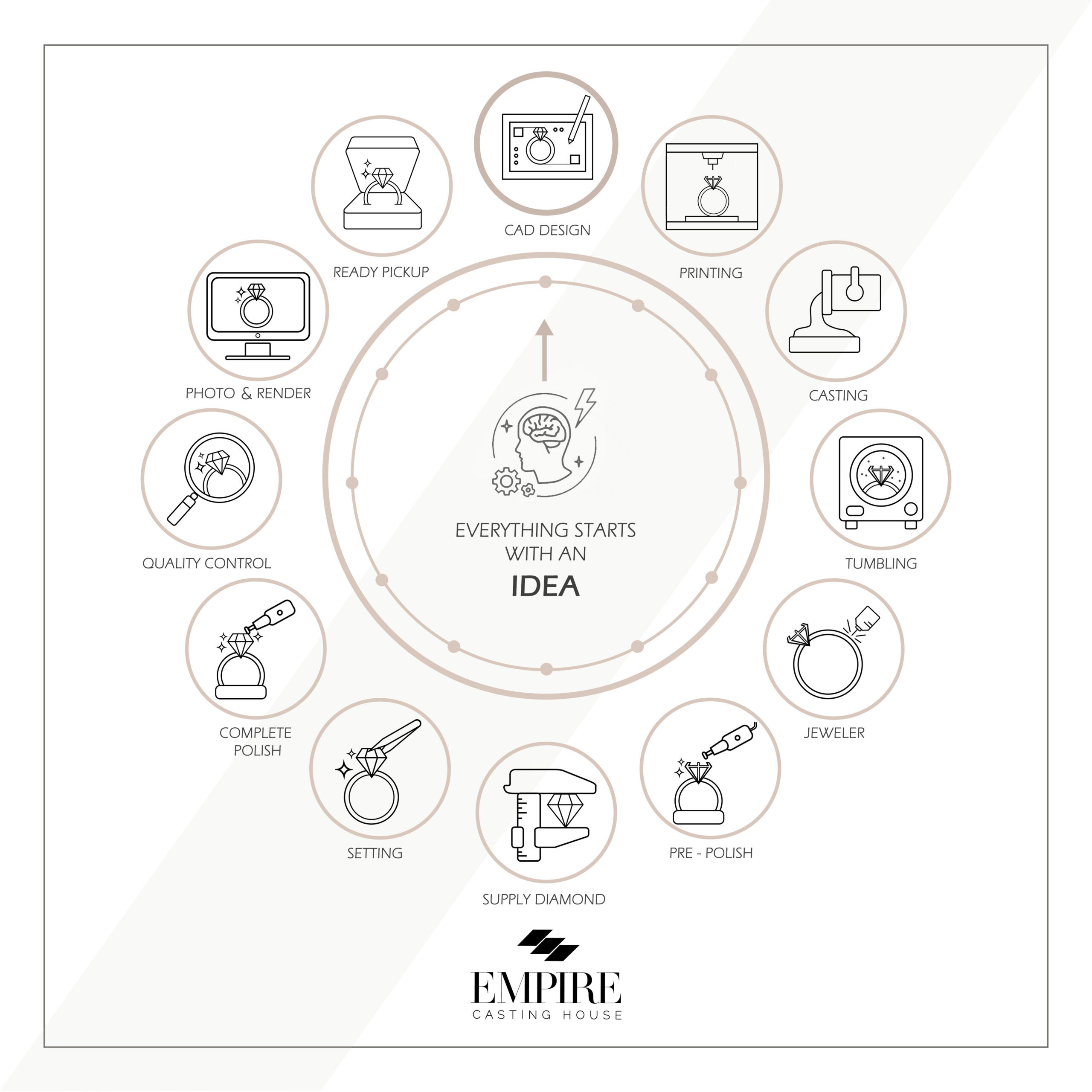

Empire Casting House is a full-service wholesale custom jewelry manufacturer serving for retail jewelers at New York City (NYC). Empire Casting House manufactures uniquely designed Engagement Rings, Wedding Bands, Necklaces, Bracelets and others, with diamond supply and start to finish services.

Our services for retailer jewelers:

CAD-Design, Printing, Casting, Tumbling, Jeweler, Pre-polish, Diamond Supply, Setting, Complete Polish, Quality Control, Photo/Render Services and Ready Pickup.

OUR SERVICES

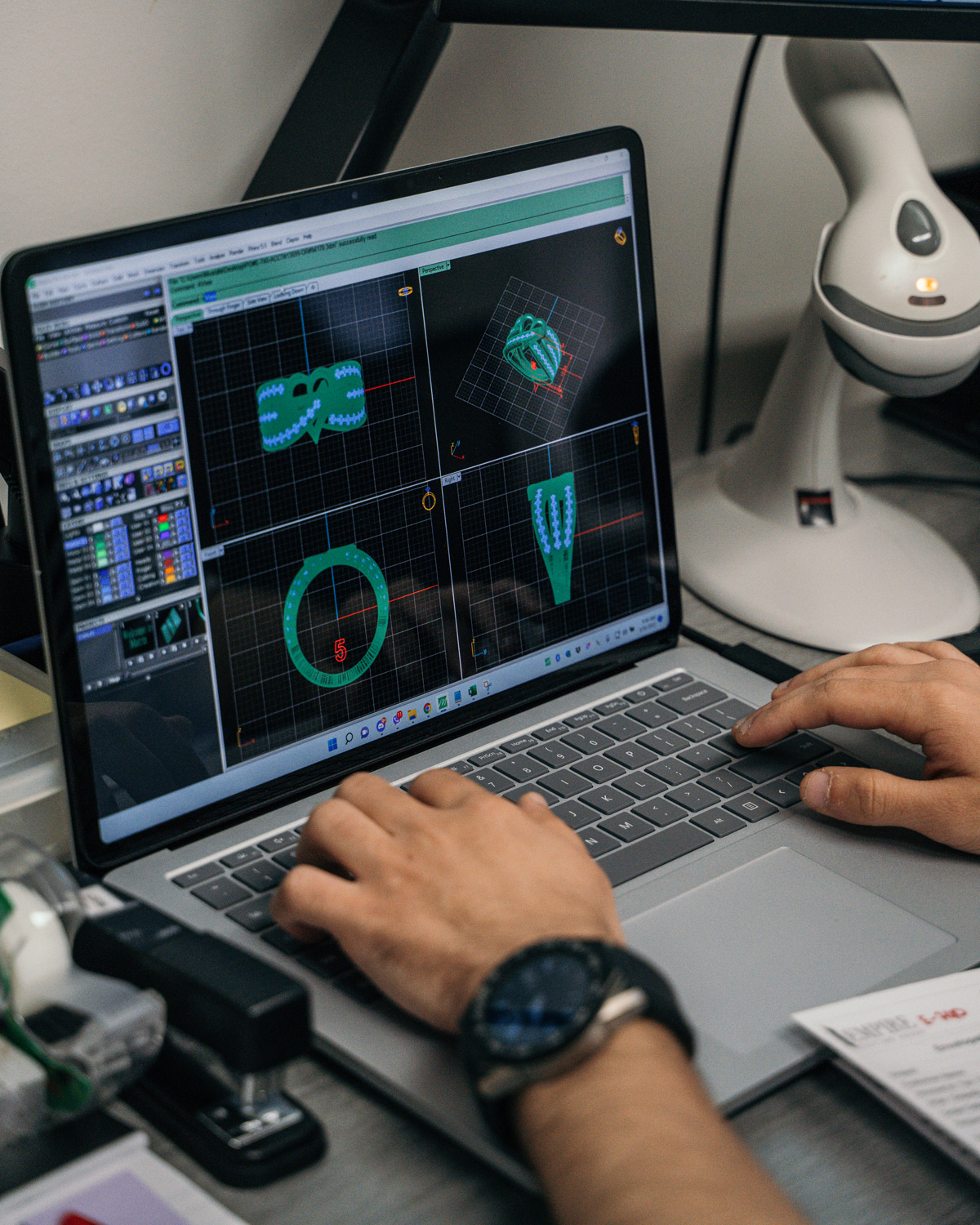

CAD Design

Sit with our in house CAD designers & create your ideal jewelry masterpiece by providing us with stone sizes dimensions to help design your idea.

LEARN MORE

Printing

Utilize our top of the line Printers available to print your STL files.

LEARN MORE

Casting

14K & 18K (Pink, White & Yellow) as well as Platinum.

LEARN MORE

Tumbling

As per your finish request we tumble & prepolish all pieces prior to setting.

LEARN MORE

Jeweler

Our team of Polishers ensure your piece(s) are prepared properly before the next step.

LEARN MORE

Pre-Polish

Our team of master jewelers ensure your piece(s) is cleaned and assembled to your quality standards.

LEARN MORE

Diamond Supply

Our in house Diamond Concierge can source a center stone or supply your melee & color stone needs.

LEARN MORE

Setting

Our team of setters are ready to set a single stone or hundreds.

LEARN MORE

Complete Polish

Our polish department ensures your product is polished to perfection.

LEARN MORE

Quality Control

Once we have completed your product(s) all pieces are run through our white glove service in our QC department to ensure there are no imperfections before completing your job.

LEARN MORE

Photo/Render Services

Check out all of our creative marketing services www.empirecreativestudio.com

Ready Pickup

Expect an email & Phone call from your preferred pick up location. Thank you for choosing us. We look forward to building your Empire together.

LEARN MORE

Full services for wholesale jewelry manufacturer in New York City (NYC)

From the heart of New York City, Empire Casting House takes your jewelry dreams from initial sketch to dazzling reality. We are your one-stop shop for everything jewelry manufacturing, offering a seamless journey from CAD design to complete polish and professional render services.

Expert Design & Technical Prowess

Our dedicated jewelry designers utilize cutting-edge CAD-CAM technology to translate your vision into precise 3D models, capturing every detail with meticulous care. Whether you have a fully formed design or just a spark of an idea, our team collaborates closely with you to bring your unique concept to life.

Unmatched Casting & Finishing

We possess unparalleled expertise in various jewelry casting techniques, ensuring we select the optimal approach for your specific piece. Our lost-wax casting process utilizes only the finest materials and rigorous quality control measures, guaranteeing exceptional durability and flawless finishes. Our skilled jewelers then employ meticulous tumbling and pre-polish techniques, followed by a complete polish that brings out the inherent brilliance and beauty of your creation.

Exquisite Diamond Accents

As a leading New York City (NYC) jewelry manufacturer, we have established strong relationships with trusted diamond suppliers, offering you access to a vast selection of ethically sourced diamonds with exceptional clarity, cut, and color. Our experienced gem setters meticulously hand-set each diamond, ensuring secure placement and unmatched sparkle.

Seamless Collaboration & Support

At Empire Casting House, we understand that every detail matters. That’s why we offer comprehensive support throughout the entire process. Our dedicated team collaborates closely with you every step of the way, ensuring your complete satisfaction. We even provide professional render services to showcase your pieces in their full glory and elevate your marketing efforts. Once your masterpiece is complete, you can conveniently pick it up directly from our New York facility.

Ready to Get Started?

Explore our individual service pages for detailed information on CAD design, printing services, casting, tumbling, jeweler services, pre-polishing, diamond supply, setting, complete polishing, quality control, and render services. Contact us today to discuss your unique project and discover how Empire Casting House, your premier New York jewelry manufacturing partner, can help you bring your vision to life.